In today’s competitive landscape, businesses constantly seek ways to improve efficiency, reduce costs, and enhance profitability. One emerging solution that holds tremendous promise is the integration of collaborative robots, or cobots, into various aspects of operations. Cobots represent a fusion of human capabilities with robotic precision, offering myriad benefits directly impacting the bottom line.

Streamlining Operations with Cobots

Cobots excel in handling repetitive and mundane tasks that are time-consuming for human workers. By automating these processes, businesses can significantly reduce labour costs and allocate human resources to more strategic endeavours. Whether it’s assembly line operations, packaging, or material handling, cobots streamline workflows and increase throughput.

Enhanced Efficiency in Production Processes

One of the most significant advantages of cobots is their ability to optimize production processes. With their precision and speed, cobots can perform tasks consistently, minimizing errors and waste. This enhanced efficiency translates into shorter lead times, increased output, and greater business profitability.

Reduction of Operational Costs Through Optimized Workflows

By integrating cobots into existing workflows, businesses can save costs across various fronts. Cobots operate 24/7 without needing breaks or overtime pay, leading to improved resource utilization and reduced labour expenses. Moreover, their compact footprint and modular design allow for efficient use of floor space, further optimizing operational costs.

Enhancing Quality and Consistency

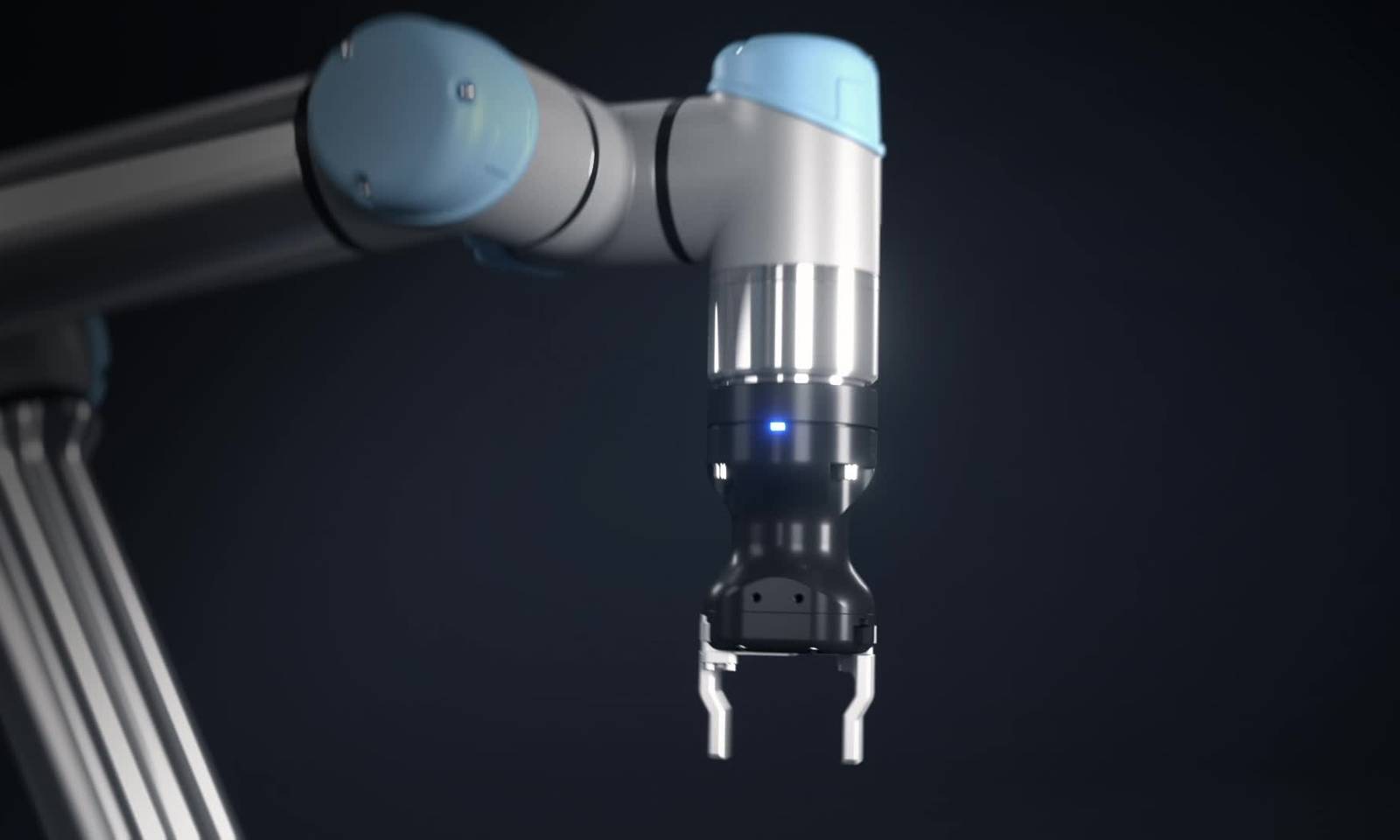

Cobots are equipped with advanced sensors and programming capabilities that enable precise execution of tasks. In manufacturing environments, this translates into tighter tolerances and higher-quality output. By minimizing variability and ensuring consistency, cobots produce defect-free products, enhancing overall quality and customer satisfaction.

Reduction of Errors and Defects

Human error is inevitable in manual labour, but cobots can help mitigate this risk significantly. Cobots minimize errors and defects in production processes through programmed routines and real-time monitoring. This reduction in rework and scrap materials not only saves costs but also preserves the reputation and integrity of the brand.

Improvement of Product Quality and Customer Satisfaction

Product quality is paramount to maintaining a competitive edge in today’s discerning market. Cobots are pivotal in upholding quality standards by executing tasks with unparalleled precision and consistency. Businesses prioritising quality assurance through cobot integration can cultivate strong customer loyalty and drive repeat business, ultimately bolstering their bottom line.

Scalability and Adaptability in Dynamic Markets

In today’s dynamic market landscape, businesses must possess the agility to adapt to changing consumer preferences and market trends. Cobots offer unparalleled flexibility, allowing businesses to scale production up or down as needed without significant retooling or reconfiguration. This adaptability enables businesses to seize new opportunities and respond swiftly to market fluctuations, maximizing profitability.

Quick Adaptation to New Production Requirements

Whether introducing new product lines or revising existing processes, cobots facilitate rapid adaptation to evolving production requirements. With their modular design and intuitive programming interfaces, cobots can be reprogrammed and redeployed with minimal downtime. This agility enables businesses to stay ahead of the curve and capitalize on emerging market opportunities effectively.

Enhancing Agility and Competitiveness in the Market

In an increasingly competitive landscape, agility is a key differentiator that separates industry leaders from laggards. By leveraging cobots to enhance operational flexibility and responsiveness, businesses can position themselves as market leaders capable of meeting evolving customer needs and outmanoeuvring competitors. This strategic advantage translates into sustained growth and profitability over the long term.

Overcoming Challenges and Implementation Considerations

While cobots offer substantial long-term benefits, the initial investment can be significant. Businesses must conduct a thorough cost-benefit analysis to evaluate the ROI of cobot integration and justify the expenditure. Capital costs, operating expenses, and projected savings should be carefully considered to make informed investment decisions.

Integration with Existing Infrastructure and Processes

Integrating cobots into existing workflows requires careful coordination and alignment with existing infrastructure and processes. Compatibility with existing automation systems, software integration, and workflow optimization are key considerations. By ensuring seamless integration, businesses can minimize disruption and maximize the efficiency gains from cobot technology.

Training and Upskilling of Workforce for Cobot Collaboration

Effective collaboration between cobots and human workers requires adequate training and upskilling initiatives. Employees must be familiarized with cobot operation, safety protocols, and troubleshooting procedures to maximize productivity and minimize errors. Investing in comprehensive training programs ensures that employees are equipped with the knowledge and skills necessary to harness the full potential of cobot technology.

Conclusion

In conclusion, the integration of cobots represents a transformative opportunity for businesses to enhance their bottom line. By streamlining operations, enhancing quality, and fostering collaboration, cobots empower businesses to achieve new efficiency, productivity, and profitability levels. As businesses navigate the complex landscape of automation, embracing cobots is not merely an investment in technology but a strategic imperative for future success.

By harnessing the power of cobots, businesses can unlock untapped potential, drive sustainable growth, and thrive in an ever-evolving marketplace. For more information on the advancements in cobots and robotics technology, explore the offerings of Aim Robotics.